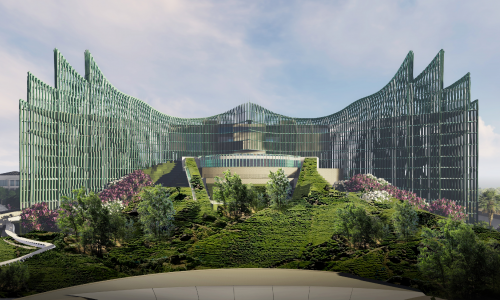

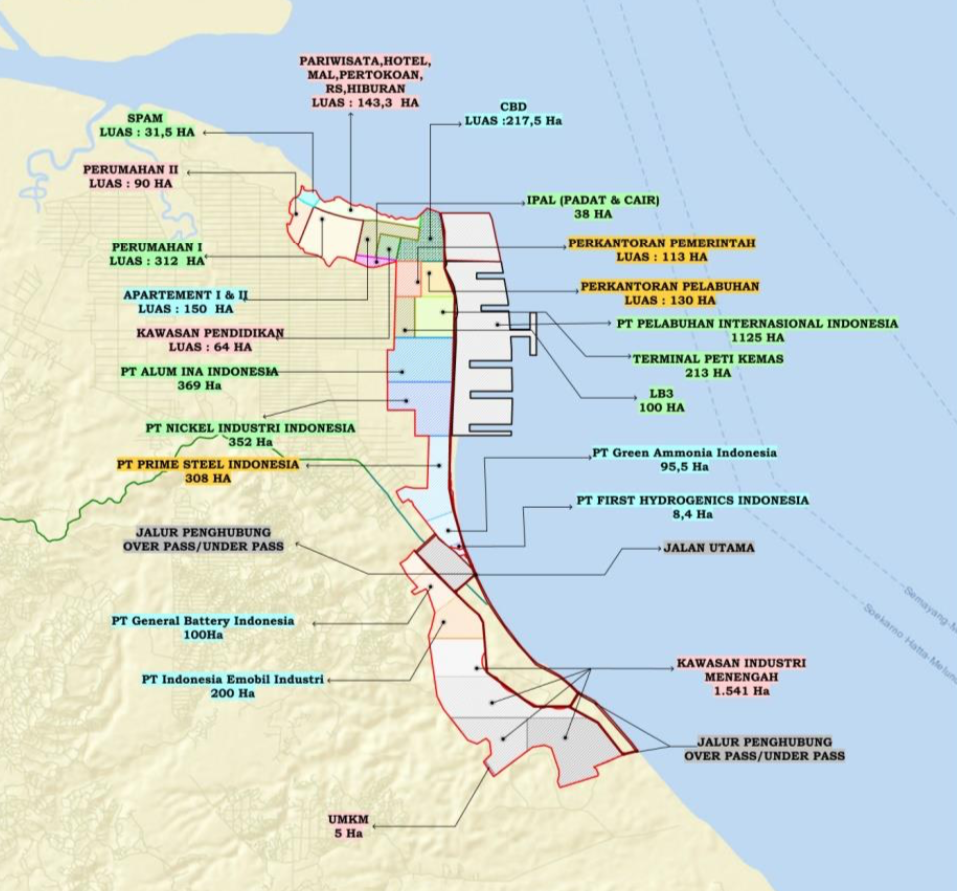

PT Indonesia Strategis Industri (ISI) – in partnership with PT Kayan Hydro Energy (KHE) and PT Pelabuhan Internasional Indonesia (PII) – plans to build a green economic zone in Tanjung Selor, North Kalimantan. By using electricity generated by KHE’s hydroelectric power plant and using materials from the construction project of the said power plants, the green economic zone will integrate multiple industries and infrastructure. The economic zone will be built in Tanah Kuning village, Mangkupadi, East Tanjung Palas, Bulungan regency, North Kalimantan.

ISI is an industrial estate development company in North Kalimantan. Together with KHE – an energy company that initiated the Kayan Cascade hydropower project which has conducted extensive studies, technical investigations and research on the 450-kilometer Kayan river in Bulungan Regency – ISI will produce cheap and environmentally friendly electricity that will be supplied to the company. ISI also partners with PII, a port company that will support the green economic zone by developing and managing the harbor in the green economic zone for its use.

Employing local workforce

The establishment and development of the Integrated Economic Zone will help increase employment opportunities for the local people in North Kalimantan. As the companies are planning to use local skilled labors, ISI also plans to establish a training center and human resource development so that the skilled, reliable and qualified Indonesians can operate and run the Integrated Economic Zone.

There are at least seven different industries and businesses that will be integrated into the economic zone, most of them are manufacturing companies. ISI will use the economic zone at earliest in 2025 or 2026 for manufacturing businesses by PT First Hydrogenics Indonesia and PT Green Ammonia Indonesia.

Building international port

PII will develop and manage the international port in the integrated green economic zone. The port development is aimed at improving services, maintaining international, national and regional logistics supplies, as well as equitable development, especially in the northern part of Kalimantan, and supporting the Indonesian government’s “Sea Highway” program.

Producing hydrogen

PT First Hydrogenics Indonesia will develop a hydrogen-producing factory in ISI’s Green Industrial Estate by using a large-scale (20 MW) Proton Exchange Membrane facility that utilizes green electricity from the Kayan Cascade hydropower plant owned by KHE and clean water provided in ISI’s Green Industrial Estate.

Producing materials for fuel cells and fertilizer

PT Green Ammonia Indonesia uses electrochemical catalysis technology to produce green ammonia from Nitrogen taken from the air and Hydrogen taken from electrolysis using the same system as PT First Hydrogenics Indonesia. Produced green ammonia can be traded as basic materials for fuel cells or fertilizers.

Producing steels

PT Prime Steel Indonesia is a limited liability company for foreign direct investment that will produce steel through two processes:

- Smelting pig iron and scrap iron/steel using Electric Arc Furnaces (EAF). The source of the pig iron is from the smelter within the project itself or an outside supplier.

- Production of high-quality steel using Vacuum Induction Melting Furnaces (VIMF). The steel forming process will produce long products and flat product mixtures from steel using a Continuous Casting Machine

PT Prime Steel Indonesia plans to build an integrated steel mill consisting of a smelter for processing iron ore and scrap iron with the final products in the form of steel billets and ingots, construction steel and iron, as well as castings that have been processed for industrial and commercial use. The mill will produce steel with an annual production rate of 4.5 million tons. It will take three phases starting with 1.5 million tons in the first phase followed by another 1.5 million tons in the second phase and 1.5 million tons in the third phase.

Producing aluminum

PT Alum Ina Indonesia is a foreign investment company working in the field of aluminum metal processing that will develop and operate an aluminum smelter in East Kalimantan. The aluminum processing process used by the company is a combination of the traditional Bayer process and the Hall-Héroult process.

Processing nickel

PT Nickel Industri Indonesia has partnered with Shandong Xinhai Technology Co. to develop a ferronickel smelter using the Rotary Kin Electric Furnace (RKEF) process with a production capacity of 6 lines, or 700,000 tons per year in ISI’s Integrated Economic Zone area.

Producing batteries

PT General Battery Indonesia is a company that focuses on the development of high-tech batteries in collaboration with technology patent holders to develop the production of the latest generation of Nickel-Metal Hydrate (NiMH), Nickel-cadmium (NiCd), and Lithium-ion batteries in Indonesia.

Producing electric vehicles

PT Indonesia Emobil Industri is planning to develop the electric transportation industry in the green economic zone, including electric cars and buses. The company will be the main tenant of the automotive heavy industry complex. It will use permanent magnet synchronous motors with an integrated control system without the need for additional gearboxes combined with a lightweight body structure made of T6082 aluminum alloy to build the world’s best electric vehicle (EV) solution.

To support the sustainability and long-term success of the automotive industry in the green economic zone, the company plans to establish a research and development center for automotive technology. Meanwhile, expert engineers will work on new vehicle designs and test the latest technologies such as drive systems and new energy sources, autonomous and intelligent vehicles, and more.